Products

-

CNC Busbar punching & shearing machine GJCNC-BP-60

Model: GJCNC-BP-60

Function: Busbar punching, shearing, embossing.

Character: Automatic, high efficiently and accurately

Output force: 600 kn

Punching speed: 130 HPM

Material size: 15*200*6000 mm

-

CNC Busbar servo bending machine GJCNC-BB-S

Model: GJCNC-BB-S

Function: Busbar level, vertical, twist bending

Character: Servo control system, high efficiently and accurately.

Output force: 350 kn

Material size:

Level bending 15*200 mm

Vertical bending 15*120 mm

-

Multifunction busbar 3 in 1 processing machine BM303-S-3-8P

Model: GJBM303-S-3-8P

Function: PLC assist busbar punching, shearing, level bending, vertical bending, twist bending.

Character: 3 unit could work at the same time. Punching unit have 8 punching dies position. Auto-calculate material length before bending process.

Output force:

Punching unit 350 kn

Shearing unit 350 kn

Bending unit 350 kn

Material size: 15*160 mm

-

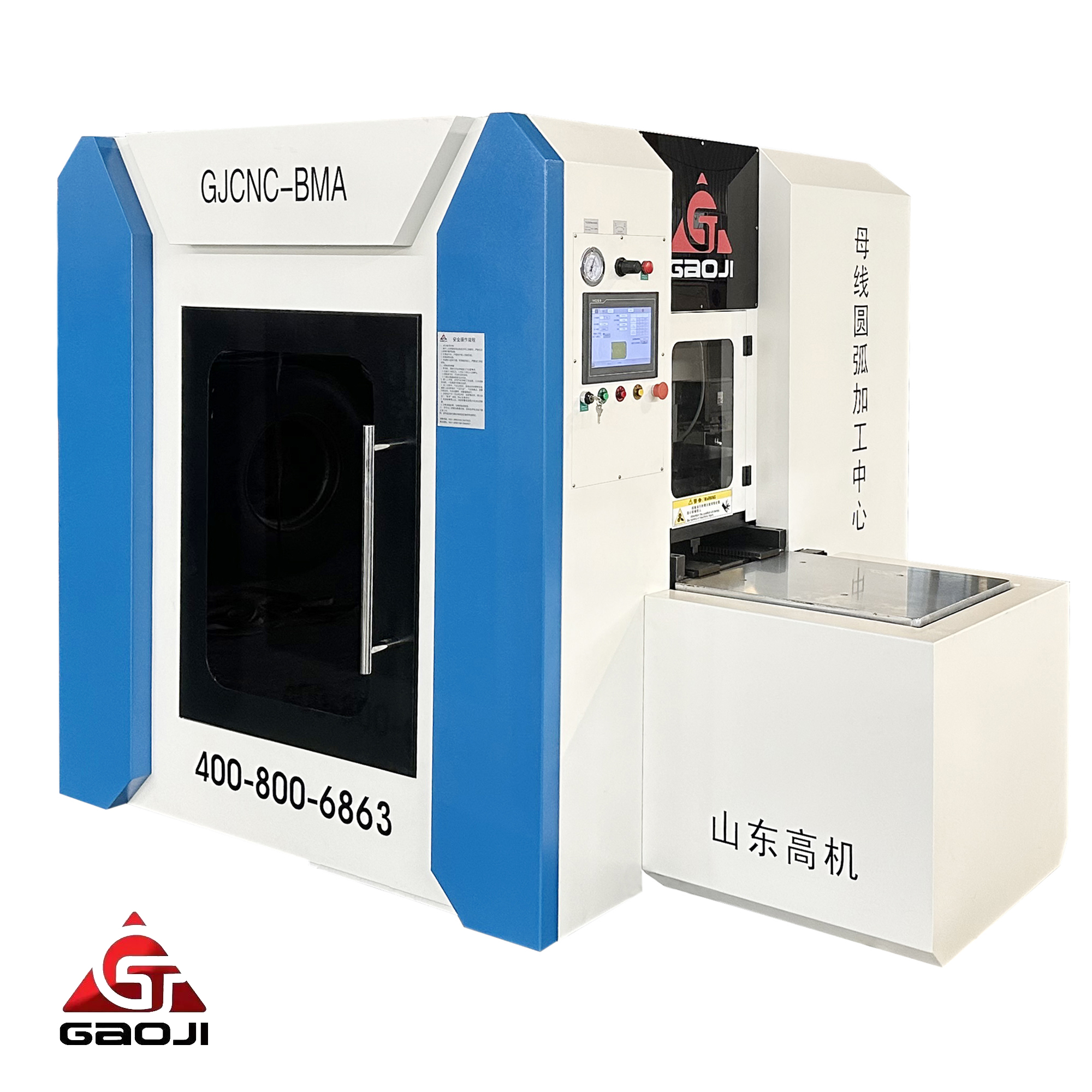

CNC Busbar Arc processing center busbar milling machine GJCNC-BMA

Model: GJCNC-BMA

Function: Automatic busbar ends Arc processing, process busbar ends with all kinds of fillet.

Character: secure the stability of workpiece, rendering a better machining surface effect.

Milling Cutter size : 100 mm

Material size:

Wideness 30~140/200 mm

Min Length 100/280 mm

Thickness 3~15 mm

-

Punching Suit for BP-50 Series

-

Applicable Models:GJCNC-BP-50

- Constituent part: Punching Suit support , Spring , Connecting Screw

-

-

Punching Suit for BM303-8P Series

- Applicable Models: BM303-S-3-8P BM303-J-3-8P

- Constituent part: Punching Suit support , Reposition block , Connecting Screw

-

Guide Sleeve of BM303-8P Series

-

Applicable Models: BM303-S-3-8P BM303-J-3-8P

- Constituent part: Guide sleeve baseplate , Guide sleeve , Reposition spring , Detach cap , Location pin .

-

-

CND Copper Rod Bending Machine 3D Bending GJCNC-CBG

Model: GJCNC-CBGFunction: Copper stick or rob flattening, punching, bending, chamfering, shearing.Character: 3D Copper stick bendingOutput force:Flattening unit 600 knPunching unit 300 knShearing unit 300 knBending unit 200 knChamfering unit 300 knMaterial size: Ø8~Ø20 copper stick -

CNC Bus Duct Flaring Machine GJCNC-BD

Model: GJCNC-BDFunction: Bus duct copper busbar bending machine, forming parallel in one time.Character: Auto feeding ,sawing and flaring functions( Other functions of punching, notching and contact riveting etc are optional )Output force:Punching 300 knNotching 300 knRiveting 300 knMaterial size:Max size 6*200*6000 mmMin size 3*30*3000 mm -

Automatic copper rod machining center GJCNC-CMC

1. Ring cabinet machining center can automatically complete the copper bar three-dimensional space multi-dimensional Angle of automatic bending, CNC punching, one-time flattening, chamfering shear and other processing technology;

2. The bending Angle of the machine is controlled automatically, the length direction of the copper rod is automatically positioned, the circumference direction of the copper rod is automatically rotated, the execution action is driven by the servo motor, the output command is controlled by the servo system, and the space multi-angle bending is truly realized.

3. The bending Angle of the machine is controlled automatically, the length direction of the copper rod is automatically positioned, the circumference direction of the copper rod is automatically rotated, the execution action is driven by the servo motor, the output command is controlled by the servo system, and the space multi-angle bending is truly realized.

-

CNC Busbar punching & shearing machine GJCNC-BP-30

Model: GJCNC-BP-30

Function: Busbar punching, shearing, embossing.

Character: Automatic, high efficiently and accurately

Output force: 300 kn

Material size: 12*125*6000 mm

-

Multifunction busbar 3 in 1 processing machine BM303-S-3

Model: GJBM303-S-3

Function: PLC assist busbar punching, shearing, level bending, vertical bending, twist bending.

Character: 3 unit could work at the same time. Auto-calculate material length before bending process.

Output force:

Punching unit 350 kn

Shearing unit 350 kn

Bending unit 350 kn

Material size: 15*160 mm