OEM Customized Multifunction Busbar Processing Shearing Punching Bending Machine (For Larger Busbar)

To be the stage of realizing dreams of our employees! To build a happier, extra united and extra professional team! To reach a mutual reward of our shoppers, suppliers, the society and ourselves for OEM Customized Multifunction Busbar Processing Shearing Punching Bending Machine (For Larger Busbar), Adhering to the business enterprise philosophy of ‘customer first, forge ahead’, we sincerely welcome consumers from at your home and abroad to cooperate with us provide you greatest services!

To be the stage of realizing dreams of our employees! To build a happier, extra united and extra professional team! To reach a mutual reward of our shoppers, suppliers, the society and ourselves for China Cutting Machine and Punching Machine, To get more information about us as well as see all our products, please visit our website. To get more information please feel free to let us know. Thank you very much and wish your business always be great!

Product Description

BM303-S-3 Series are multifunction busbar processing machines designed by our company (patent number: CN200620086068.7), and the first turret punching machine in China. This equipment could do punching, shearing and bending all at the same time.

Advantage

With appropriate dies, the punching unit could process round, oblong and square holes or emboss a 60*120mm area on busbar.

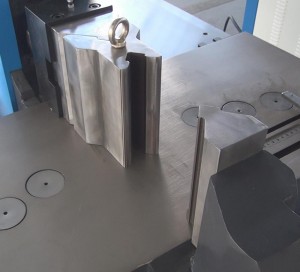

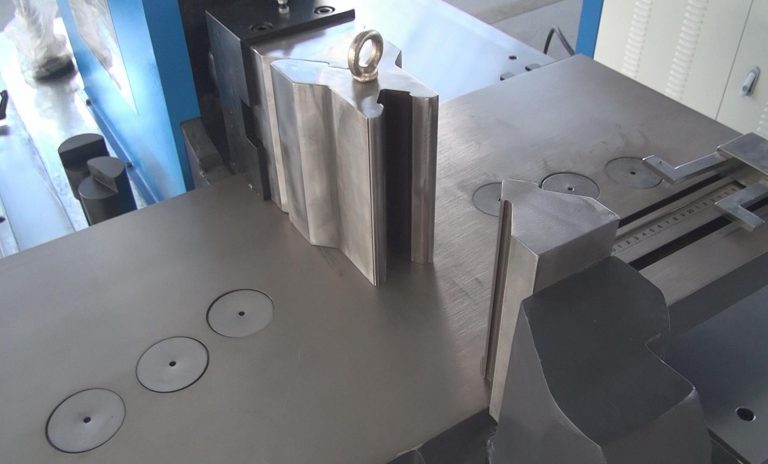

This unit adopts turret-type die kit, capable of storing eight punching or embossing dies, the operator could select one punching dies within 10 seconds or completely replace the punching dies within 3 minutes.

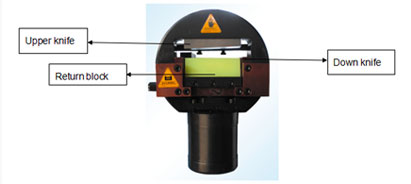

The shearing unit choose the single shear method, make no scrap while shearing the material.

And this unit adopts round integral structure which is effective and capable of long service life.

The bending unit could process level bending, vertical bending, elbow pipe bending, connecting terminal, Z-shape or twist bending by change the dies.

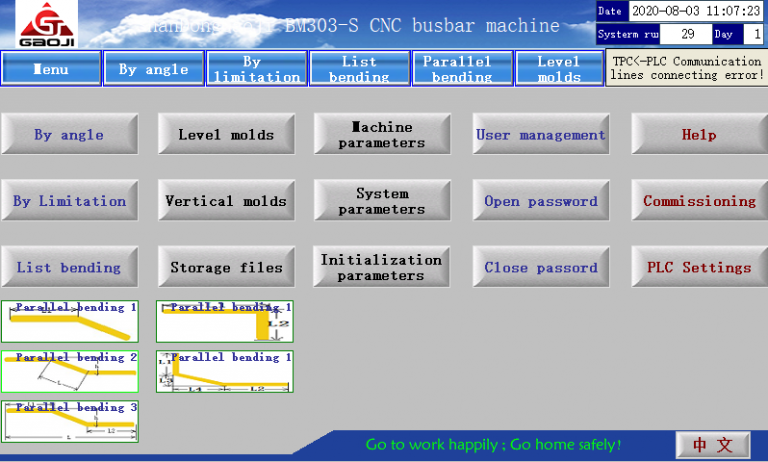

This unit is designed to be controlled by PLC parts, these parts cooperate with our control program could ensure you have easy operate experience and high accuracy workpiece, and the whole bending unit placed on a independent platform which ensure all three units could work at the same time.

Control panel, man-machine interface: he software is simple to operate, has a storage function, and is convenient for repeated operations. The machining control adopts the numerical control method, and the machining accuracy is high.

To be the stage of realizing dreams of our employees! To build a happier, extra united and extra professional team! To reach a mutual reward of our shoppers, suppliers, the society and ourselves for OEM Customized Multifunction Busbar Processing Shearing Punching Bending Machine (For Larger Busbar), Adhering to the business enterprise philosophy of ‘customer first, forge ahead’, we sincerely welcome consumers from at your home and abroad to cooperate with us provide you greatest services!

OEM Customized China Cutting Machine and Punching Machine, To get more information about us as well as see all our products, please visit our website. To get more information please feel free to let us know. Thank you very much and wish your business always be great!

Configuration

| Work Bench Dimension (mm) | Machine Weight (kg) | Total Power (kw) | Working Voltage (V) | Number of Hydraulic Unit (Pic*Mpa) | Control Model |

| Layer I: 1500*1200Layer II: 840*370 | 1460 | 11.37 | 380 | 3*31.5 | PLC+CNCangel bending |

Main Technical Parameters

| Material | Processing Limite (mm) | Max Output Force (kN) | ||

| Punching unit | Copper / Aluminum | ∅32 (thickness≤10) ∅25 (thickness≤15) | 350 | |

| Shearing unit | 15*160 (Single Shearing) 12*160 (Punching Shearing) | 350 | ||

| Bending unit | 15*160 (Vertical Bending) 12*120 (Horizontal Bending) | 350 | ||

| * All three units could be chosen or modify as customization. | ||||