Recently, Shandong Gaoji Industrial Machinery Co., Ltd. welcomed guests from afar. Li Jing, vice president of the company, and relevant leaders of the technical Department warmly received him.

Before this meeting, the company communicated with customers and partners in Saudi Arabia for a long time. Based on the trust and support of both sides, the customer specially sent their professional technician Mr. Peter to Jinan, Shandong Province, to conduct a professional inspection of our company’s busbar processing equipment.

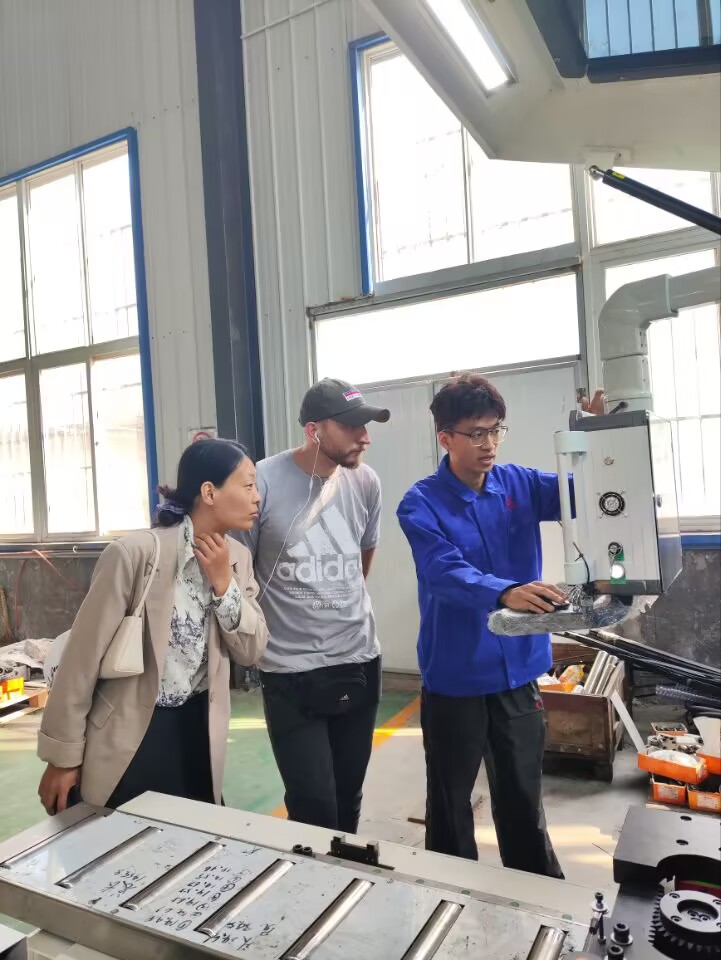

Mr. Peter had an in-depth discussion with the technical engineers on the technical issues of the product

During the discussion with the technical engineer, Mr. Peter highly appreciated the technical details of our products, especially when the technical engineer introduced the design drawing of the CNC busbar punching and cutting machine and the supporting programming software – GJ3D developed by Shandong High Machine, Mr. Peter showed a very strong interest. He was very impressed with the high precision that our equipment could achieve. Subsequently, Mr. Peter, led by General Manager Li, visited the factory workshop on site.

Mr. Peter and technical engineers discuss GJ3D programming software on site

During the whole site visit, Mr. Peter was very serious and made a professional inspection of the busbar processing equipment of Shandong Gaoji. Especially for the details of the equipment, he made a very detailed communication with the technical engineers and the technical workers present. After the professional introduction of the technical department and the actual viewing of the operation of the equipment, Mr. Peter repeatedly praised the busbar processing machine of our company.

Watch the machining operation of CNC busbar punching and cutting machine and busbar arc machining center (Angle milling machine) on site

The multi-function busbar processing machine (BM303-S-S-3-8P) was studied in detail

At the end of the trial operation of the equipment, Mr. Peter also inspected the workpiece generated by the operation very carefully, and took photos of the workpiece effect one by one. In the process of workpiece processing, Mr. Peter asked our technical engineers and technical workers about the stroke of the main and auxiliary pliers of the CNC busbar punching and cutting machine, the structure of the mold library, the working principle of the CNC busbar bending machine and the busbar arc machining center (Angle milling machine), and the station structure and operation mode of the multi-functional busbar processing machine represented by BM303-S-3-8P. As well as a series of professional technical issues such as the size range of the busbar that can be processed by various types of equipment, it can be said that it is professional to every detail.

Mr. Peter’s careful inspection of the workpiece and photo retention

After a full day of field investigation and in-depth communication, Mr. Peter was very satisfied with the busbar machine of Shandong Gaoji. After further negotiation and communication with Mr. Li and engineers, he finalized the basic cooperation direction in the later stage. The on-site exchange and inspection was successfully concluded.

Mr. Peter listened carefully to the explanation of the technical engineer of our company again, and discussed the details of the later cooperation with Mr. Li.

The two sides reached further cooperation intention.

Post time: Apr-09-2024