Wire everyone has seen, there are thick and thin, widely used in work and life. But what are the wires in the high-voltage distribution boxes that provide us with electricity? How is this special wire made? At Shandong Gaoji Industrial Machinery Co., LTD., we found the answer.

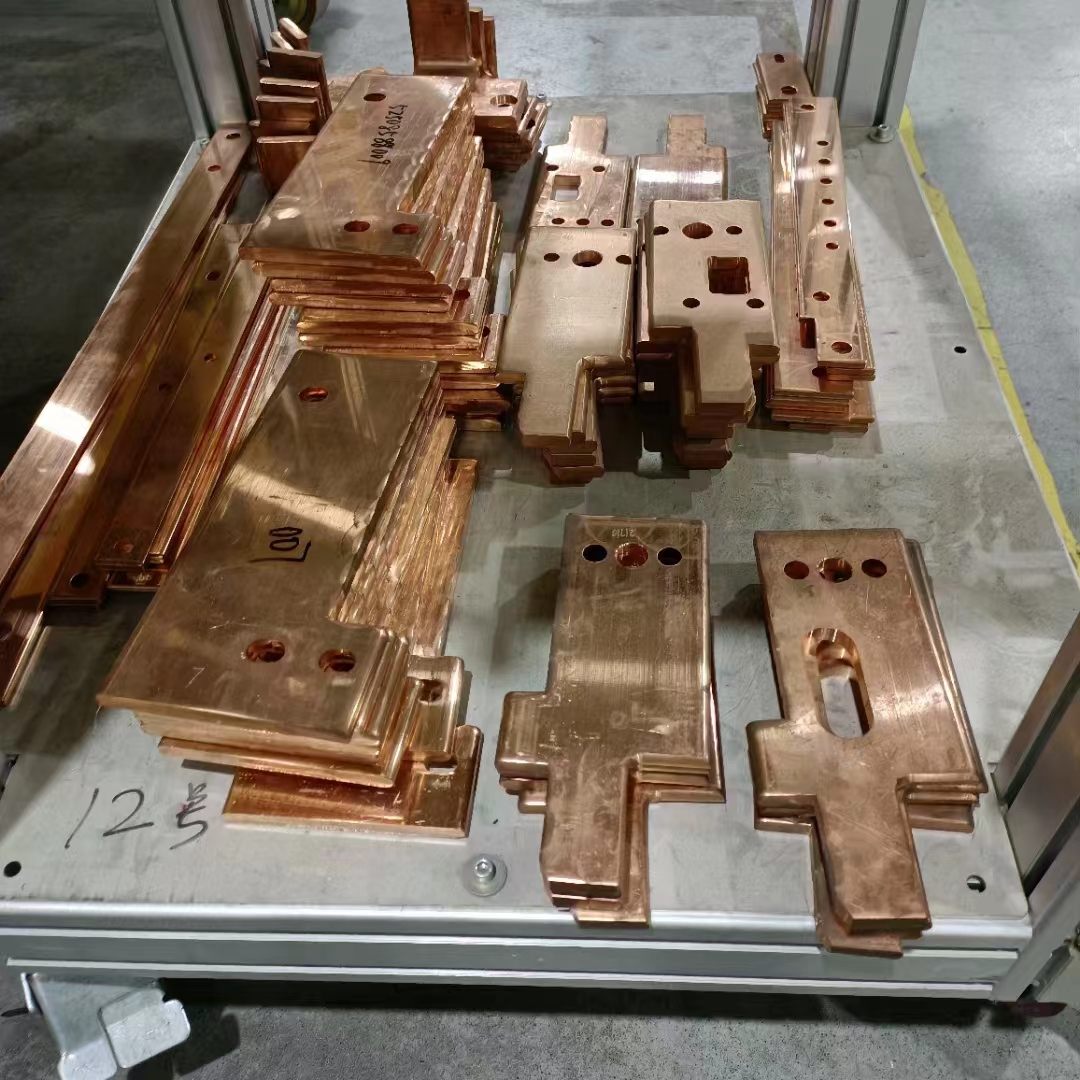

“This thing is called the bus bar, which is the conductive material on the power distribution cabinet equipment, and can be understood as the ‘wire’ of the high-voltage distribution box.” The minister of the gas Department of Shandong Gao Electromechanical said, “The wires in our daily life are thin, and the curved lines are very simple. And this busbar row you can see, very long and heavy, according to the actual application, it needs to cut to different lengths, different apertures, bending different angles, milling out different radians and other processing processes.”

On the production floor, engineers show how a copper bar can be turned into a power accessory. “In front of this is our company’s fist product – bus processing intelligent production line. First of all, the processing technology of the bus bar is drawn on the server, after the instruction is issued, the production line is started, the bus bar is automatically accessed from the intelligent library to automatically take material and load material, the bus bar is transmitted to the CNC bus punching and cutting machine, the stamping, cutting, marking and other processes are completed, and each workpiece processed is transmitted to the laser marking machine, and the relevant information is engraved to facilitate product traceability. The workpiece is then transferred to a fully automatic arc machining center, where it is machined to complete the angular arc machining, which is a process to remove the tip discharge phenomenon. Finally, the bus bar is transmitted to the automatic CNC bus bending machine, and the bending process of the bus bar is automatically completed. An unmanned assembly line efficiently and accurately processes the bus rows, and the entire process is fully automated without human intervention.”

It sounds like the process is very complicated, but after the actual boot processing, each piece can be processed in just 1 minute. This rapid efficiency is due to the automation of the entire production process. “The current company’s products are all automated. On these machines, we are equipped with special computers and independently developed programming software. In actual production, design drawings can be imported into the computer, or directly programmed on the machine, and the machine will produce according to the drawings, so that the accuracy of the product can reach 100%.” ‘said the engineer.

In the interview, the CNC bus punching and cutting machine left a deep impression. It is very like a battleship, very beautiful, and very atmospheric. In this regard, the engineer smiled and said: “This is another feature of our products, while ensuring production, but also to be beautiful and generous.” The engineer said that this kind of beauty is not only beautiful on the outside, but also has practical use. “For example, on the punching and shearing machine, where it looks like a window on a warship, we actually designed it to be open. In this way, if the machine fails, it will be easy to repair and replace. Another example is the cabinet door next to it, which looks good and is more convenient to use. After opening it, the power system is inside. For some small failures, we can help customers deal with them by remote support, which greatly improves production efficiency.” Finally, the engineer pointed to the intelligent production line in front of the introduction, each machine on this line, both can be connected for overall production, can also be disassembled stand-alone operation, this design is almost “unique” in the country, the intelligent production line has also been rated as the first (set) technical equipment in Shandong Province in 2022, “in a word, all our designs, It’s all about making things easier for our customers.”

With intelligent technology research and development, advanced process flow and humanized design concept, for more than 20 years, Shandong high Machine has provided a variety of different forms of bus processing equipment for domestic and foreign markets. At present, the company has more than 60 independent research and development of patented technology, the domestic market share of more than 70%, while exporting to more than a dozen countries and regions in the world, was awarded the Shandong Province high-tech enterprises, Shandong Province specialized special new enterprises and other honorary titles.

For the future development of the enterprise, the engineer is full of confidence: “We will focus on intelligent processing, unmanned workshops and other fields in the future, continue to improve technological innovation and design research and development capabilities, and strive to provide the market with more and better intelligent, convenient and beautiful industrial equipment, and contribute their own strength to the manufacturing power.”

Post time: Oct-25-2024