For the busbar processing equipment, the mold plays a crucial role in the use process. However, due to the different operation methods, coupled with the increase in service life and frequency, these important components are prone to damage. In order to ensure the life and efficiency of metal processing equipment, the daily maintenance of the mold is essential.

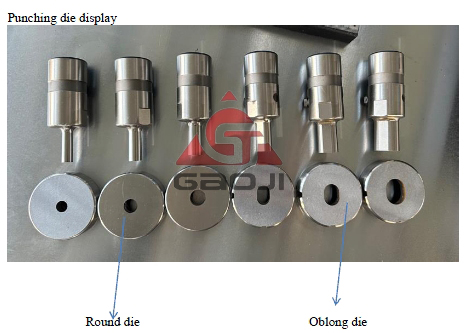

punching die

The wear and tear of the mold due to repeated use may lead to the failure of the workpiece product and the equipment shutdown, which will inevitably cause losses to the production. Therefore, regular maintenance can not only extend the service life of the mold, but also improve the overall performance of the equipment. Here are some key practices to incorporate into your daily maintenance routine.

* * 1. Cleaning: ** At the end of each production cycle, it is essential to thoroughly clean the mold. Metal residues can build up, causing corrosion and affecting the integrity of the mold. Use an appropriate cleaning agent compatible with the mold material to prevent damage.

* * 2. Inspection: ** Daily visual inspection of the mold. Look for signs of wear, cracks, or any irregularities. Early detection of problems can prevent more serious problems and save time and resources. If necessary, replace the mold in time to avoid greater damage to the equipment itself.

* * 3. Lubrication: ** Proper lubrication is essential to reduce friction and wear. Grease moving parts and joints to ensure smooth operation. This approach not only protects the mold, but also improves the efficiency of the metal processing equipment.

* * 4. Temperature control: ** Monitor the temperature during mold operation. Overheating can cause warping or other forms of damage. The implementation of temperature control measures helps to maintain the structural integrity of the mold.

* * 5. ** Keep maintenance logs to track inspections, repairs and any problems encountered. This document can provide valuable insight into the performance of the mold and help in planning future maintenance.

In short, the daily maintenance of molds is the key to metal processing equipment. Through cleaning, inspection, lubrication, temperature control and documentation, the risk of damage can be significantly reduced and optimum performance ensured. Investing time in these practices not only increases productivity, but also contributes to the overall success of metalworking operations. In addition, when purchasing new equipment, you may wish to choose several sets of molds as inventory for emergency needs.

Post time: Oct-14-2024