What is CNC bus processing equipment?

CNC busbar machining equipment is a special mechanical equipment for processing busbars in power system. Busbars are important conductive components used to connect electrical equipment in power systems and are usually made of copper or aluminum. The application of numerical control (CNC) technology makes the processing process of the bus more accurate, efficient and automatic.

This device usually has the following functions:

Cutting: Precise cutting of the bus according to the set size and shape.

Bending: The bus can be bent at various angles to adapt to different installation needs.

Punch holes: Punch holes in the bus bar for easy installation and connection.

Marking: Marking on the bus bar to facilitate subsequent installation and identification.

Advantages of CNC bus processing equipment include:

High precision: Through the CNC system, high precision machining can be achieved and human error can be reduced.

High efficiency: Automatic processing improves production efficiency and shortens processing time.

Flexibility: Can be programmed according to different needs, to adapt to a variety of bus processing requirements.

Reduce material waste: Precise cutting and processing can effectively reduce material waste.

What are some CNC bus processing equipment?

CNC Automatic Busbar processing line:Automatic production line for busbar processing.

GJBI-PL-04A

Fully automatic busbar extracting library:Busbar automatic loading and unloading device.

GJAUT-BAL-60×6.0

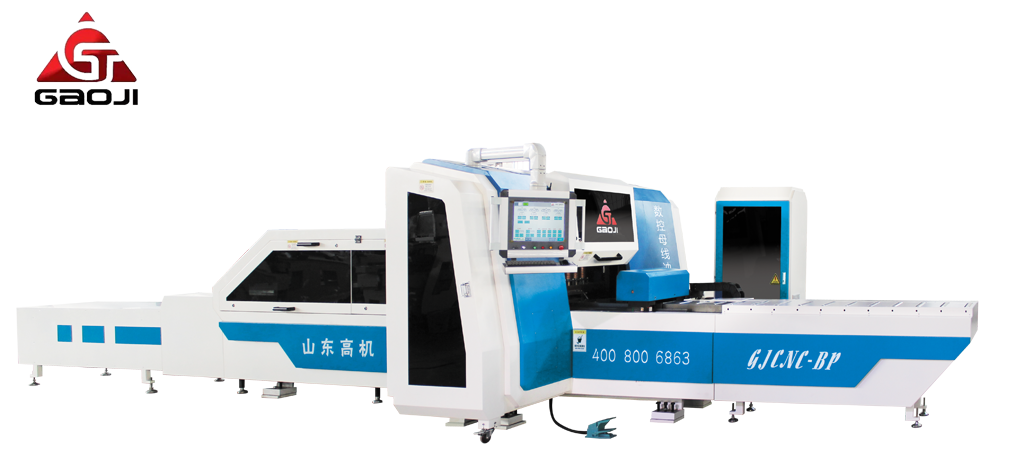

CNC Busbar Punching and Shearing Machine:CNC busbar punching, cutting, embossing, etc.

GJCNC – BP-60

CNC busbar bending machine:CNC busbar row bend flat, vertical bending, twisting, etc.

GJCNC-BB-S

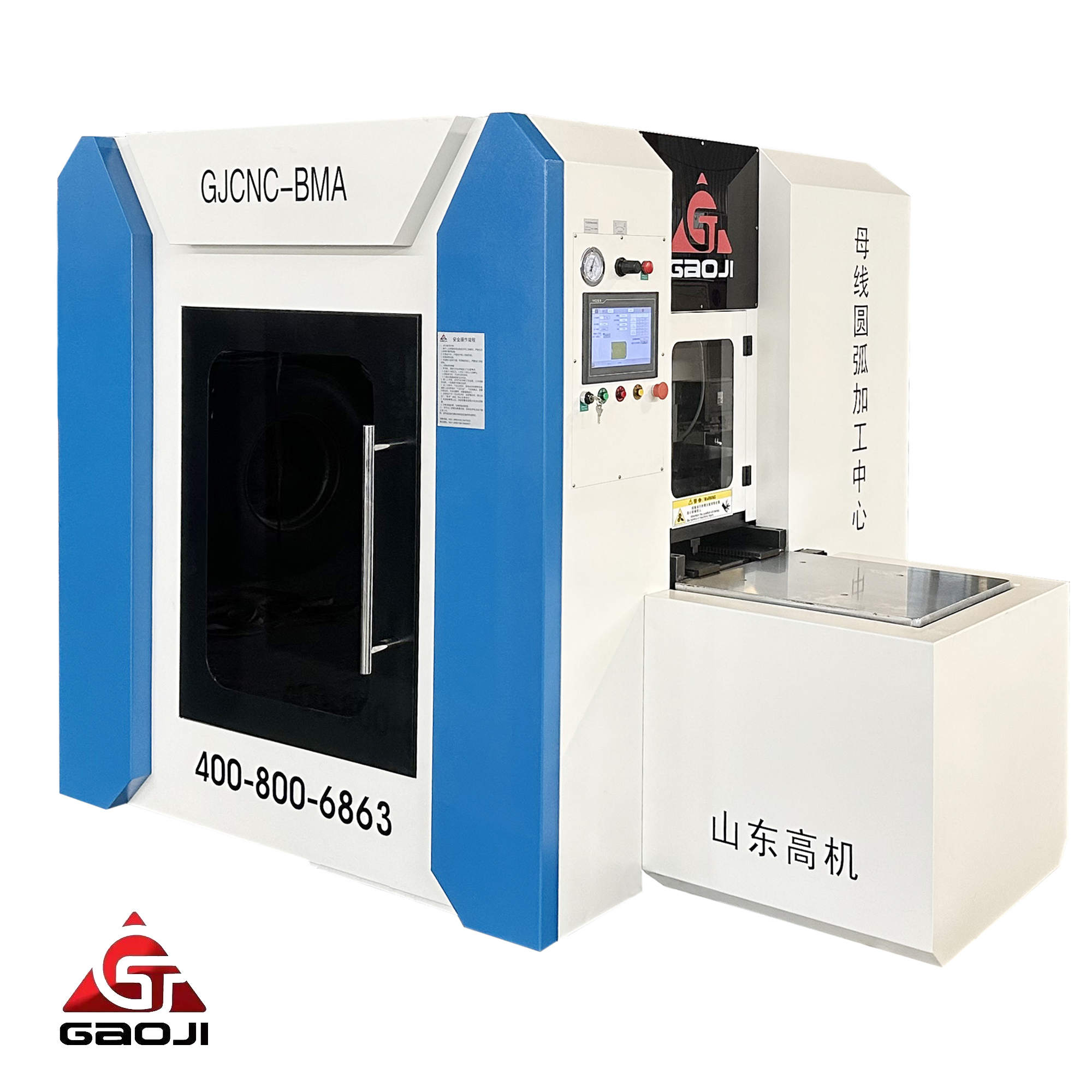

Bus Arc Machining Center (Chamfering Machine):CNC arc Angle milling equipment

GJCNC-BMA

Post time: Oct-30-2024

1.jpg)