Manufactur standard Multifunction 3-1 Metal Busbar Bending Cutting Punching Processing Machine

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for Manufactur standard Multifunction 3-1 Metal Busbar Bending Cutting Punching Processing Machine, We have now experienced manufacturing facilities with a lot more than 100 workers. So we are able to guarantee short lead time and good quality assurance.

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for China Busbar Machine and 3-1 Busbar Machine, Abiding by our motto of “Hold well the quality and services, Customers Satisfaction”, So we present our clients with high quality products and excellent service. Make sure you feel free to contact us for further information.

Product Description

BM303-S-3 Series are multifunction busbar processing machines designed by our company (patent number: CN200620086068.7), and the first turret punching machine in China. This equipment could do punching, shearing and bending all at the same time.

Advantage

With appropriate dies, the punching unit could process round, oblong and square holes or emboss a 60*120mm area on busbar.

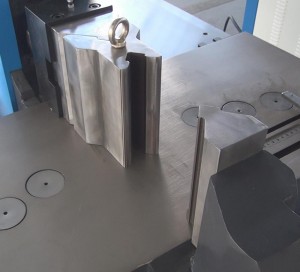

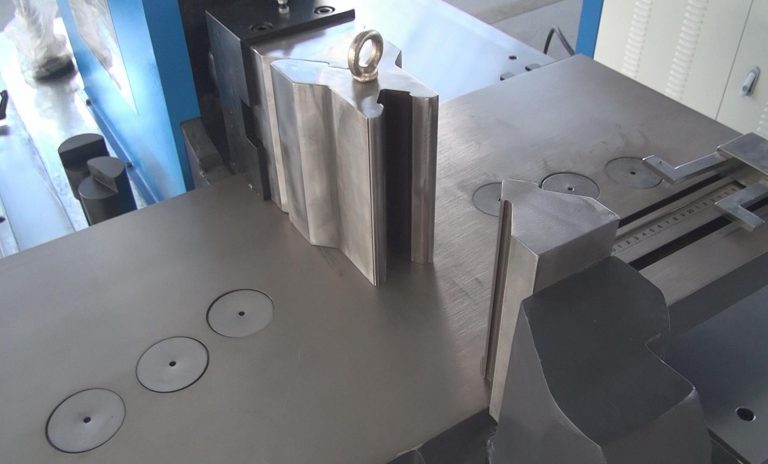

This unit adopts turret-type die kit, capable of storing eight punching or embossing dies, the operator could select one punching dies within 10 seconds or completely replace the punching dies within 3 minutes.

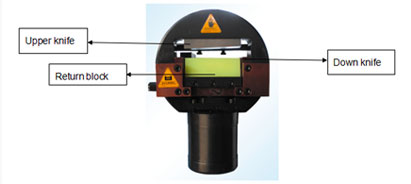

The shearing unit choose the single shear method, make no scrap while shearing the material.

And this unit adopts round integral structure which is effective and capable of long service life.

The bending unit could process level bending, vertical bending, elbow pipe bending, connecting terminal, Z-shape or twist bending by change the dies.

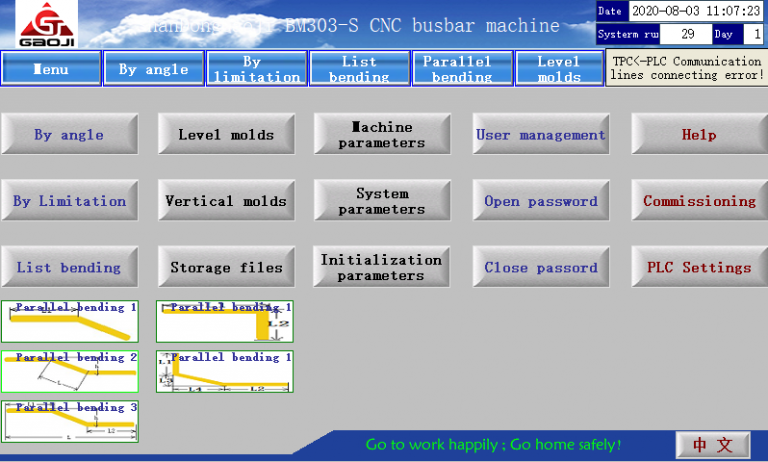

This unit is designed to be controlled by PLC parts, these parts cooperate with our control program could ensure you have easy operate experience and high accuracy workpiece, and the whole bending unit placed on a independent platform which ensure all three units could work at the same time.

Control panel, man-machine interface: he software is simple to operate, has a storage function, and is convenient for repeated operations. The machining control adopts the numerical control method, and the machining accuracy is high.

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for Manufactur standard Multifunction 3-1 Metal Busbar Bending Cutting Punching Processing Machine, We have now experienced manufacturing facilities with a lot more than 100 workers. So we are able to guarantee short lead time and good quality assurance.

Manufactur standard China Busbar Machine and 3-1 Busbar Machine, Abiding by our motto of “Hold well the quality and services, Customers Satisfaction”, So we present our clients with high quality products and excellent service. Make sure you feel free to contact us for further information.

Configuration

| Work Bench Dimension (mm) | Machine Weight (kg) | Total Power (kw) | Working Voltage (V) | Number of Hydraulic Unit (Pic*Mpa) | Control Model |

| Layer I: 1500*1200Layer II: 840*370 | 1460 | 11.37 | 380 | 3*31.5 | PLC+CNCangel bending |

Main Technical Parameters

| Material | Processing Limite (mm) | Max Output Force (kN) | ||

| Punching unit | Copper / Aluminum | ∅32 (thickness≤10) ∅25 (thickness≤15) | 350 | |

| Shearing unit | 15*160 (Single Shearing) 12*160 (Punching Shearing) | 350 | ||

| Bending unit | 15*160 (Vertical Bending) 12*120 (Horizontal Bending) | 350 | ||

| * All three units could be chosen or modify as customization. | ||||