CNC Busbar punching & shearing machine GJCNC-BP-30

Product Details

GJCNC-BP-30 is a professional equipment designed to process busbar efficiently and accurately.

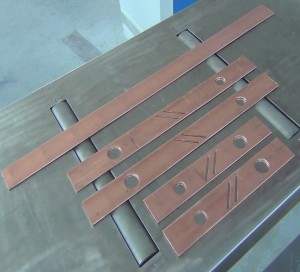

With those processing dies in the tool library, this equipment could process busbar by punching (round hole, oblong hole etc), embossing, shearing, grooving, cutting filleted corner and so on. The finished workpiece will be delivered by the conveyor.

This equipment can match with CNC bending machine and form busbar processing production line.

Main Character

The transport system adopt master-slave clamp structure with automatic clamp switch technology, the maximun stroke of main clamp is 1000mm, when finish the whole process the machine will use flip table to slide the workpiece out, these structures make it highly effective and precise especially for long busbar.

The processing system include the tool library and the hydraulic work station. The tool library could contain 4 punching dies and 1 shearing die, and the bantam library ensure the process more efficient when the dies changes frequently, and a lot more simple and convenient when you need to change or replace the punchine dies. The hydraulic work station adopt new technology such like differential pressure system and energy storage device, these new device will make the equipment more efficiency and reduce the energy loss during processing.

As the control system we have GJ3D program which is a special aided design software of busbar processing. Which could auto program machine code, calculate every date in processing, and show you the simulation of the whole process which will present the change of busbar step by step clearly. These characters made it convenient and powerful to avoid complicated manual coding with machine language. And it is able to demonstrate the whole process and effectively prevent material wast cause by incorrect input.

For years out company took the lead on apply 3D graphic technique to busbar processing industry. Now we can present to you the best cnc control and design software in Asian.

Extendablenodes part

External marking machine:It can be placed independently outside the machine and integrated control to GJ3d system. The machine could change the working depth or content such like graphics, text, product serial number, trademark, etc. according to customer requirements.

Die lubricating device: Used for the lubrication of punches, especially avoid the punches getting stuck in the busbar during the processing. especially for aluminum or composite busbar.

Main Technical Parameters

| Dimension (mm) | 3000*2050*1900 | Weight (kg) | 3200 | Certification | CE ISO | ||

| Main Power (kw) | 12 | Input Voltage | 380/220V | Power Source | Hydraulic | ||

| Output Force (kn) | 300 | Punching Speed (hpm) | 60 | Control Axis | 3 | ||

| Max Material Size (mm) | 6000*125*12 | Max Punching Dies | 32mm | ||||

| Location Speed(X axis) | 48m/min | Stroke of Punching Cylinder | 45mm | Positioning Repeatability | ±0.20mm/m | ||

| Max Stroke(mm) | X AxisY AxisZ Axis | 1000530350 | AmountofDies | PunchingShearing | 4/51/1 | ||

Configuration

| Control Parts | Transmission Parts | ||

| PLC | OMRON | Precision linear Guide | Taiwan HIWIN |

| Sensors | Schneider electric | Precision the ball screw (4th series) | Taiwan HIWIN |

| Control Button | OMRON | Ball screw support beaning | Japanese NSK |

| Touch Screen | OMRON | Hydraulic Parts | |

| Computer | Lenovo | High-pressure Electromagnetic Valve | Italy |

| AC Contactor | ABB | High pressure tubing | Rivaflex |

| Circuit Breaker | ABB | High pressure pump | AIbert |

| Servo Motor | YASKAWA | The control software and 3D support software | GJ3D (3D support software designed all by our company) |

| Servo Driver | YASKAWA | ||