China Wholesale High-Speed Aluminum Busbar Processing Machine Manufacturers - Best-Selling China Hydraulic Multifunction Punching Bending Cutting Busbar Machine for Copper with 380V Power Supply – Gaoji

China Wholesale High-Speed Aluminum Busbar Processing Machine Manufacturers - Best-Selling China Hydraulic Multifunction Punching Bending Cutting Busbar Machine for Copper with 380V Power Supply – Gaoji Detail:

We preserve increasing and perfecting our solutions and service. At the same time, we function actively to do research and growth for Best-Selling China Hydraulic Multifunction Punching Bending Cutting Busbar Machine for Copper with 380V Power Supply, Honesty is our principle, expert operation is our perform, support is our goal, and customers’ fulfillment is our future!

We preserve increasing and perfecting our solutions and service. At the same time, we function actively to do research and growth for China Busbar Machine, Now we have more than 10 years exported experience and our merchandise have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

Product Description

BM603-S-3 Series are multifunction busbar processing machine designed by our company. This equipment could do punching, shearing and bending all at the same time, and specially designed for large size busbar processing.

Advantage

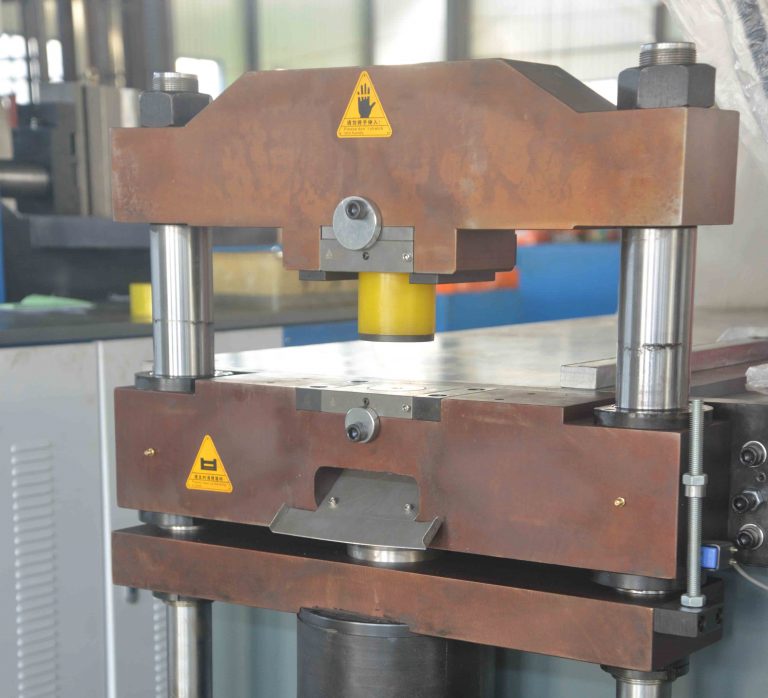

The punching unit adopt column frame, bear reasonable force, can effectively ensure long-term use without deformation. Punching die instal hole was processed by numerical control machine which will ensure high precision and long life, and a lot of process such like round hole, long round hole, square hole, double hole punching or embossing could be completed by changing the die.

The shearing unit also adopt column frame that will provide more power for the knife, the upper and lower knife was installed vertical parallelly, the single shearing mode ensure the kerf smooth with no waste.

The bending unit could process level bending, vertical bending, elbow pipe bending, connecting terminal, Z-shape or twist bending by change the dies.

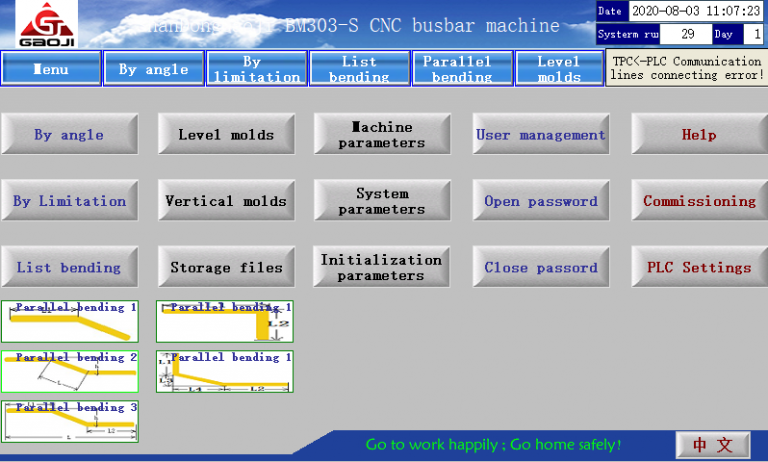

This unit is designed to be controlled by PLC parts, these parts cooperate with our control program could ensure you have easy operate experience and high accuracy workpiece, and the whole bending unit placed on a independent platform which ensure all three units could work at the same time.

Control panel, man-machine interface: he software is simple to operate, has a storage function, and is convenient for repeated operations. The machining control adopts the numerical control method, and the machining accuracy is high.

We preserve increasing and perfecting our solutions and service. At the same time, we function actively to do research and growth for Best-Selling China Hydraulic Multifunction Punching Bending Cutting Busbar Machine for Copper with 380V Power Supply, Honesty is our principle, expert operation is our perform, support is our goal, and customers’ fulfillment is our future!

Best-Selling China Busbar Machine, Now we have more than 10 years exported experience and our merchandise have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

Product detail pictures:

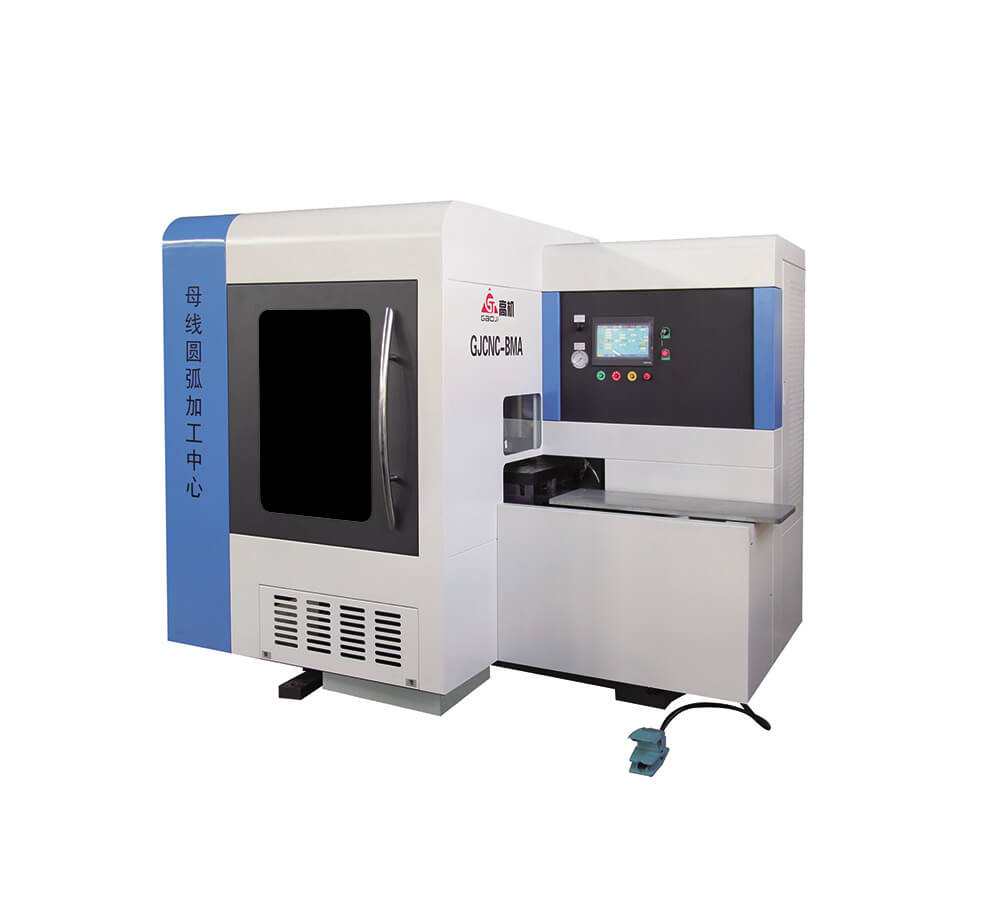

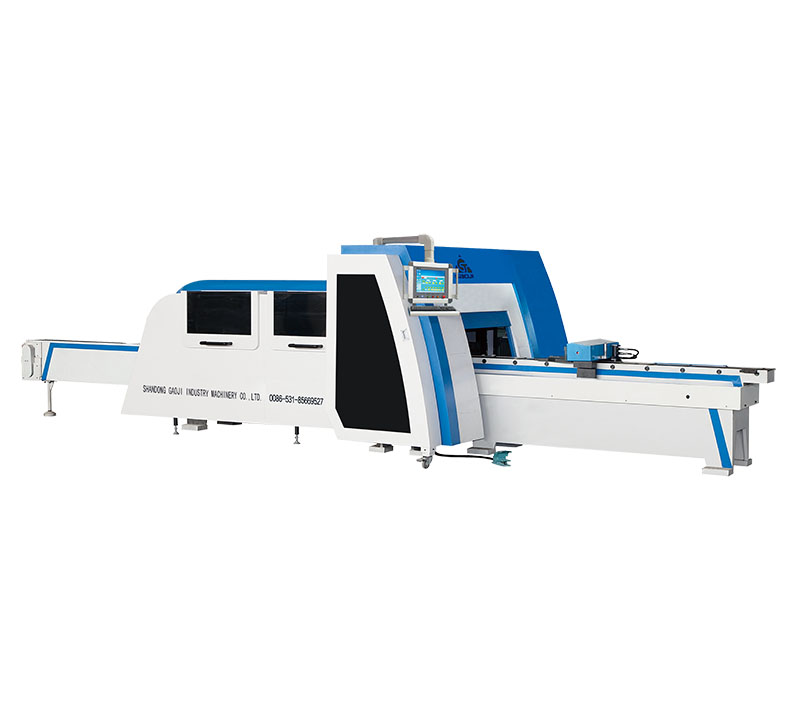

Related Product Guide:

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for China Wholesale High-Speed Aluminum Busbar Processing Machine Manufacturers - Best-Selling China Hydraulic Multifunction Punching Bending Cutting Busbar Machine for Copper with 380V Power Supply – Gaoji, The product will supply to all over the world, such as: Nigeria, Liberia, Uruguay, Our domestic website's generated over 50, 000 purchasing orders every year and quite successful for internet shopping in Japan. We would be happy to have an opportunity to do business with your company. Looking forward to receiving your message !

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.