China Wholesale Copper Pipe Bender Factories - Multifunction busbar 3 in 1 processing machine BM603-S-3-CS – Gaoji

China Wholesale Copper Pipe Bender Factories - Multifunction busbar 3 in 1 processing machine BM603-S-3-CS – Gaoji Detail:

Product Description

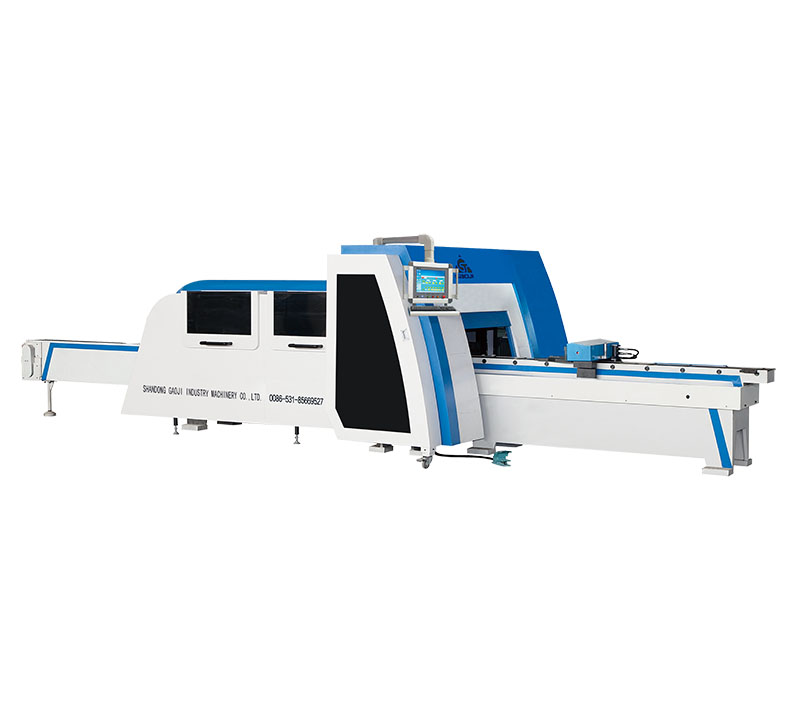

BM603-S-3 Series are multifunction busbar processing machine designed by our company. This equipment could do punching, shearing and bending all at the same time, and specially designed for large size busbar processing.

Advantage

The punching unit adopt column frame, bear reasonable force, can effectively ensure long-term use without deformation. Punching die instal hole was processed by numerical control machine which will ensure high precision and long life, and a lot of process such like round hole, long round hole, square hole, double hole punching or embossing could be completed by changing the die. And also could flattening or shearing copper stick.

The shearing unit choose the single shear method, make no scrap while shearing the material.

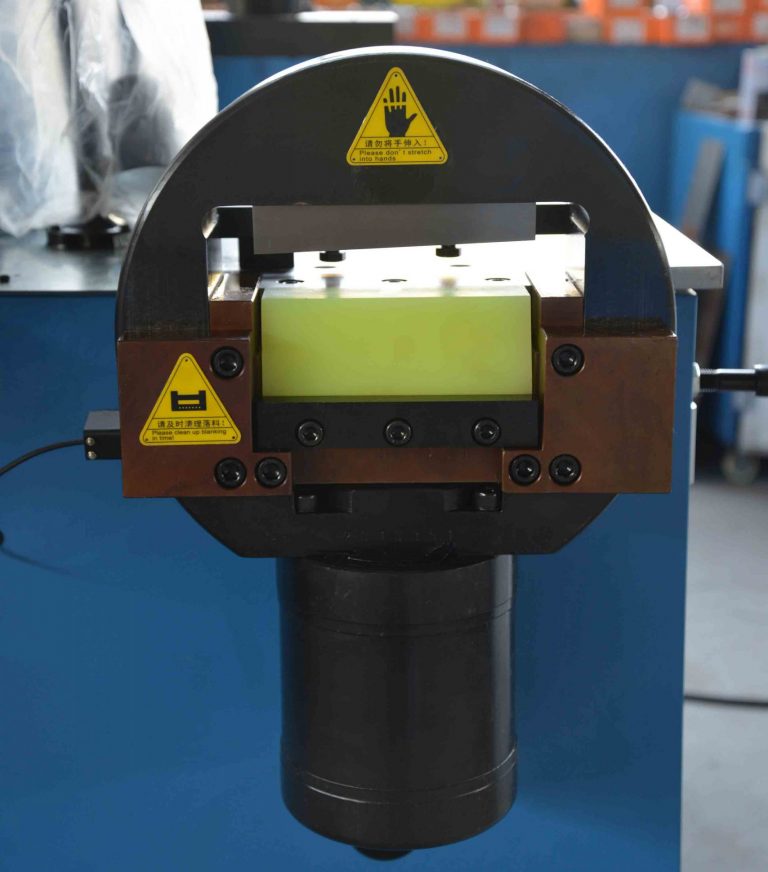

And this unit adopts round integral structure which is effective and capable of long service life.

The bending unit could process level bending, vertical bending, elbow pipe bending, connecting terminal, Z-shape or twist bending by change the dies.

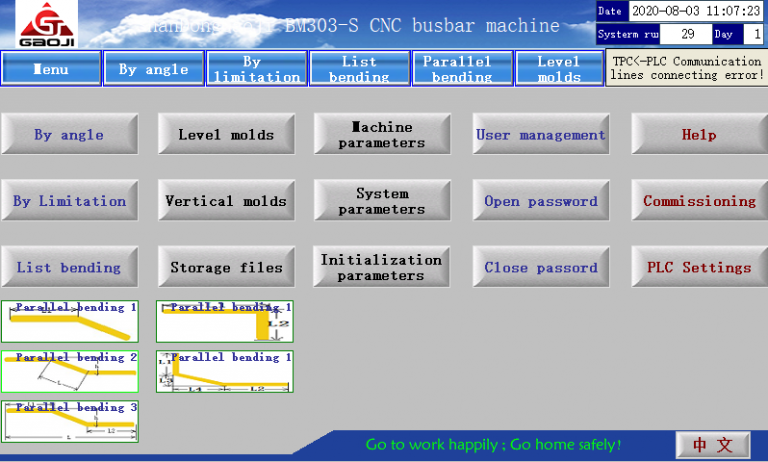

This unit is designed to be controlled by PLC parts, these parts cooperate with our control program could ensure you have easy operate experience and high accuracy workpiece, and the whole bending unit placed on a independent platform which ensure all three units could work at the same time.

The bending unit could process level bending, vertical bending, elbow pipe bending, connecting terminal, Z-shape or twist bending by change the dies.

This unit is designed to be controlled by PLC parts, these parts cooperate with our control program could ensure you have easy operate experience and high accuracy workpiece, and the whole bending unit placed on a independent platform which ensure all three units could work at the same time.

Control panel, man-machine interface: he software is simple to operate, has a storage function, and is convenient for repeated operations. The machining control adopts the numerical control method, and the machining accuracy is high.

Product detail pictures:

Related Product Guide:

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for China Wholesale Copper Pipe Bender Factories - Multifunction busbar 3 in 1 processing machine BM603-S-3-CS – Gaoji, The product will supply to all over the world, such as: Milan, Orlando, Brazil, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.