China Wholesale Cnc Copper Busbar Milling Suppliers - China Multifunction CNC Busbar Processing Machine – Gaoji

China Wholesale Cnc Copper Busbar Milling Suppliers - China Multifunction CNC Busbar Processing Machine – Gaoji Detail:

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for China Multifunction CNC Busbar Processing Machine, We welcome an opportunity to do business with you and hope to have pleasure in attaching further details of our products.

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for China Busbar Processing Machine, Selling our solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

Product Description

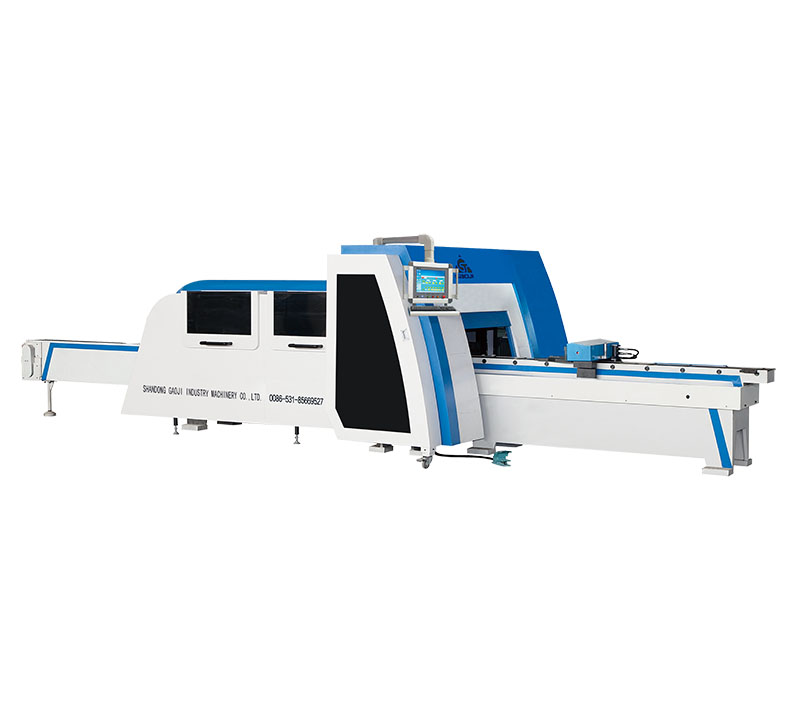

BM303-S-3 Series are multifunction busbar processing machines designed by our company (patent number: CN200620086068.7), and the first turret punching machine in China. This equipment could do punching, shearing and bending all at the same time.

Advantage

With appropriate dies, the punching unit could process round, oblong and square holes or emboss a 60*120mm area on busbar.

This unit adopts turret-type die kit, capable of storing eight punching or embossing dies, the operator could select one punching dies within 10 seconds or completely replace the punching dies within 3 minutes.

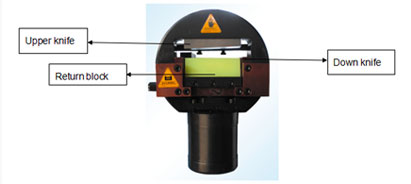

The shearing unit choose the single shear method, make no scrap while shearing the material.

And this unit adopts round integral structure which is effective and capable of long service life.

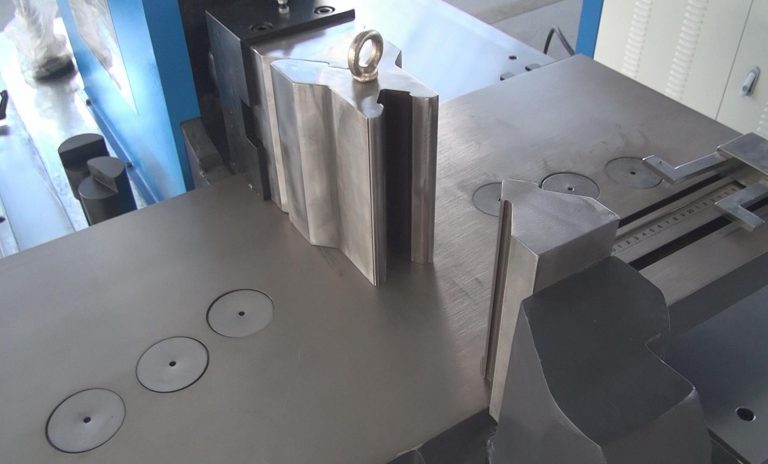

The bending unit could process level bending, vertical bending, elbow pipe bending, connecting terminal, Z-shape or twist bending by change the dies.

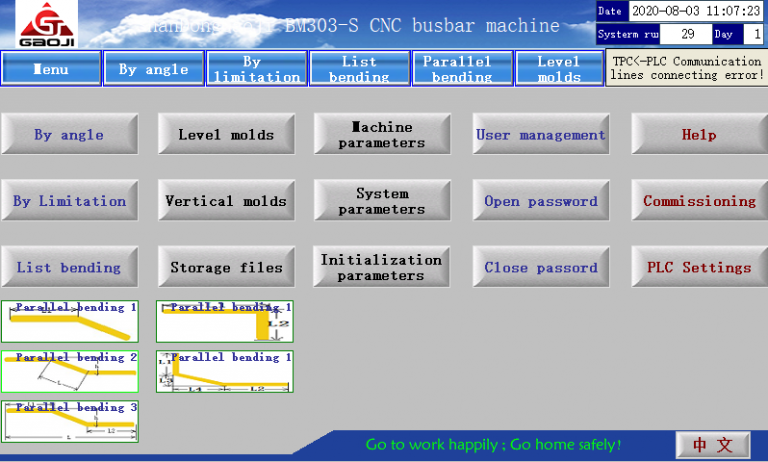

This unit is designed to be controlled by PLC parts, these parts cooperate with our control program could ensure you have easy operate experience and high accuracy workpiece, and the whole bending unit placed on a independent platform which ensure all three units could work at the same time.

Control panel, man-machine interface: he software is simple to operate, has a storage function, and is convenient for repeated operations. The machining control adopts the numerical control method, and the machining accuracy is high.

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for China Multifunction CNC Busbar Processing Machine, We welcome an opportunity to do business with you and hope to have pleasure in attaching further details of our products.

China Busbar Processing Machine, Selling our solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for China Wholesale Cnc Copper Busbar Milling Suppliers - China Multifunction CNC Busbar Processing Machine – Gaoji, The product will supply to all over the world, such as: Vietnam, French, Doha, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.