China Wholesale Busbar Twist Bending Quotes - Quots for China Hydraulic Busbar Punching and Shearing Machine for Copper Aluminum – Gaoji

China Wholesale Busbar Twist Bending Quotes - Quots for China Hydraulic Busbar Punching and Shearing Machine for Copper Aluminum – Gaoji Detail:

No matter new shopper or old customer, We believe in very long expression and dependable relationship for Quots for China Hydraulic Busbar Punching and Shearing Machine for Copper Aluminum, We hope we can easily have a friendly partnership with businessman from all around the globe.

No matter new shopper or old customer, We believe in very long expression and dependable relationship for Busbar Punching And Shearing Machine, China Busbar Machine, We accomplish this by exporting our wigs directly from our own factory to you. The goal of our company is to get customers who enjoy coming back to their business. We sincerely hope to cooperate with you in the near future. If there’s any opportunity, welcome to visit our factory!!!

Product Details

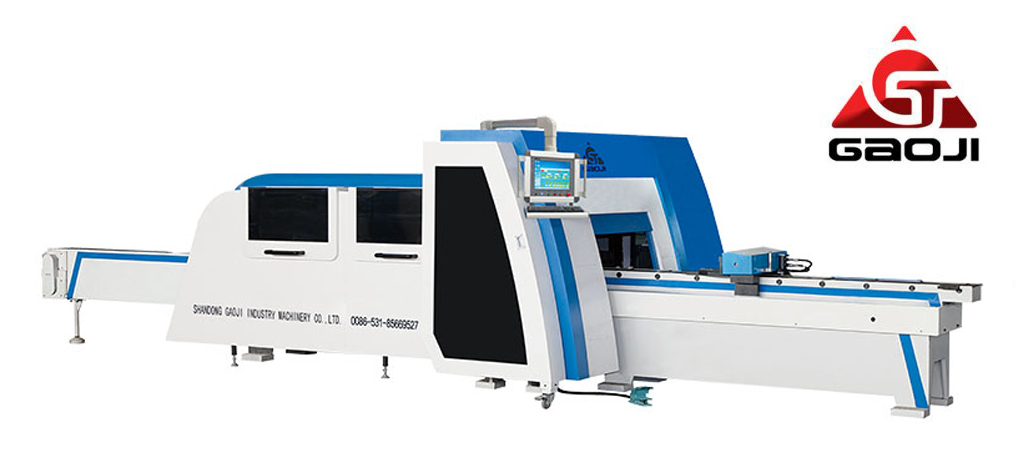

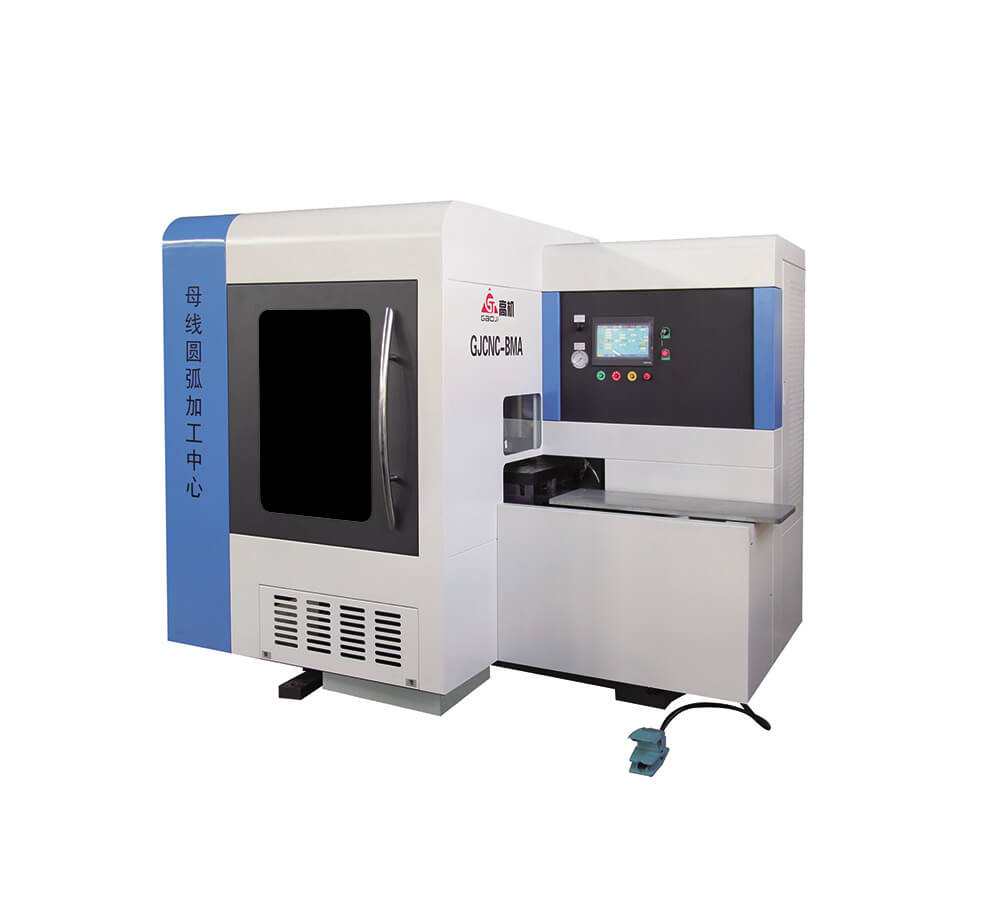

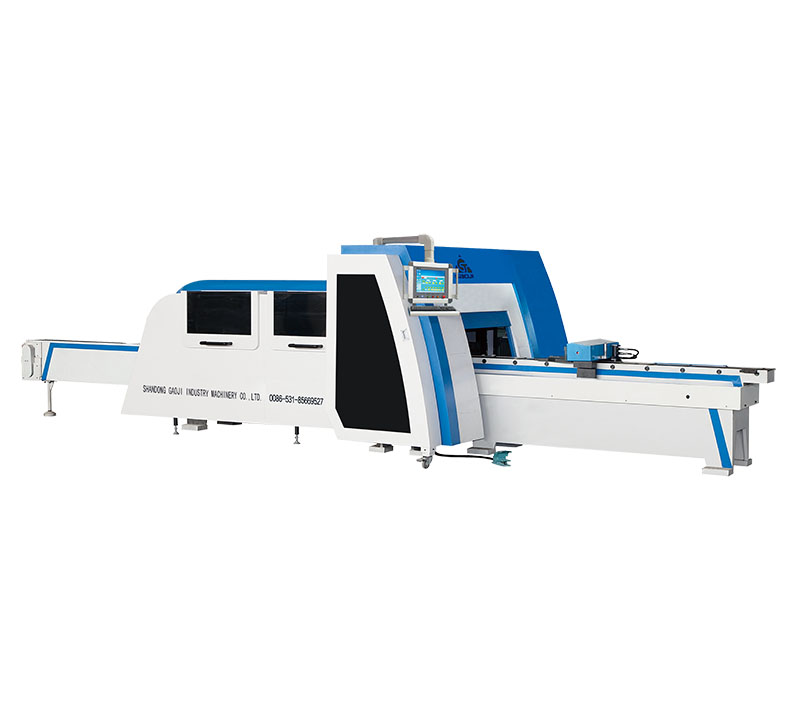

GJCNC-BP-50 is a professional equipment designed to process busbar efficiently and accurately.

During processing this equipment could automatically replace the clamps, which is highly effective especially for long busbar. With those processing dies in the tool library, this equipment could process busbar by punching (round hole, oblong hole etc), embossing, shearing, grooving, cutting filleted corner and so on. The finished workpiece will be delivered by the conveyor.

This equipment can match with CNC bender and form busbar processing production line.

Main Character

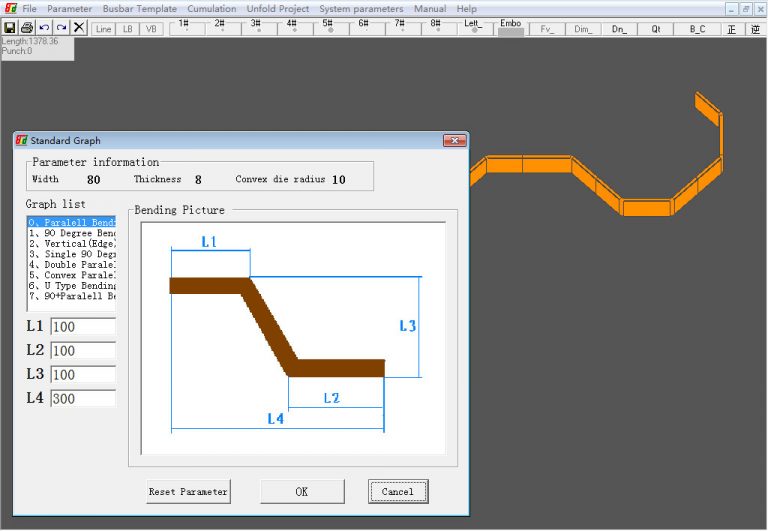

GJ3D / programming software

GJ3D is a special aided design software of busbar processing. Which could auto program machine code, calculate every date in processing, and show you the simulation of the whole process which will present the change of busbar step by step clearly. These characters made it convenient and powerful to avoid complicated manual coding with machine language. And it is able to demonstrate the whole process and effectively prevent material wast cause by incorrect input.

For years out company took the lead on apply 3D graphic technique to busbar processing industry. Now we can present to you the best cnc control and design software in Asian.

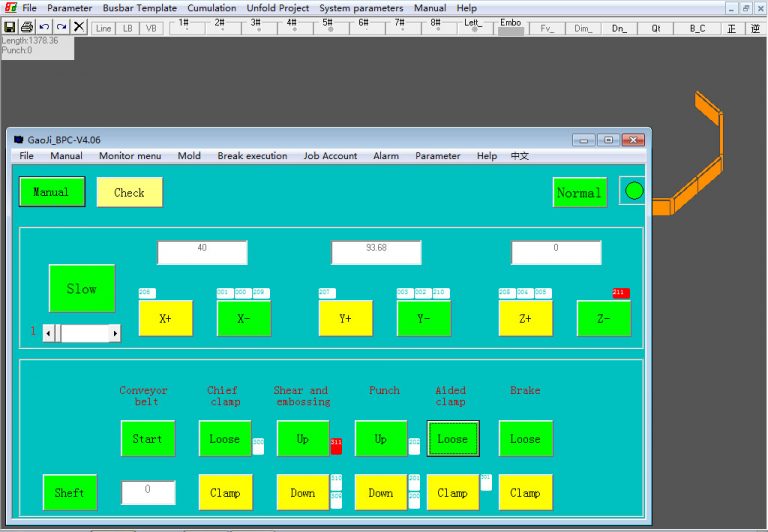

Human-computer interface

In order to present better operation experience and more useful information. The equipment has a 15” RMTP as human-computer interface. With this unit you can have clear information of the whole manufacture process or any alarm might happen and control the equipment by single hand.

If you need to modify the equipment’s setup information or basic die parameters. You can also input the date with this unit.

Mechanical Structures

Inorder to create a steady, effective, precision and long life time mechanical structure, we choose high accurate ball screw, precision linear guide by Taiwan HIWIN and servo system by YASKAWA plus our unique two clamp system. All these above create a transmission system as good as you need.

We develop auto-replace program in order to make the clamp system more effective especially for long busbar processing, and also could maximum reduce operator’s work. Create more value for our customer.

There are two types:

GJCNC-BP-50-8-2.0/SC (Six punching, a shear, a pressing )

GJCNC-BP-50-8-2.0/C (Eight punching, a shear )

You can choose you need models

Export Packing

No matter new shopper or old customer, We believe in very long expression and dependable relationship for Quots for China Hydraulic Busbar Punching and Shearing Machine for Copper Aluminum, We hope we can easily have a friendly partnership with businessman from all around the globe.

Quots for China Busbar Machine, Busbar Punching and Shearing Machine, We accomplish this by exporting our wigs directly from our own factory to you. The goal of our company is to get customers who enjoy coming back to their business. We sincerely hope to cooperate with you in the near future. If there’s any opportunity, welcome to visit our factory!!!

Product detail pictures:

Related Product Guide:

To create more value for customers is our business philosophy; customer growing is our working chase for China Wholesale Busbar Twist Bending Quotes - Quots for China Hydraulic Busbar Punching and Shearing Machine for Copper Aluminum – Gaoji, The product will supply to all over the world, such as: Rotterdam, Mexico, Puerto Rico, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, please kindly contact us, we are looking forward to building up a great business relationship with you.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!