China Wholesale Busbar Processing Equipment Pricelist - China Equipment From China CNC Hydraulic Multifunction Busbar Processing Machine – Gaoji

China Wholesale Busbar Processing Equipment Pricelist - China Equipment From China CNC Hydraulic Multifunction Busbar Processing Machine – Gaoji Detail:

No matter new buyer or aged buyer, We believe in prolonged expression and trustworthy relationship for China Equipment From China CNC Hydraulic Multifunction Busbar Processing Machine, We welcome customers all around the word to speak to us for long run company interactions. Our items are the best. Once Selected, Perfect Forever!

No matter new buyer or aged buyer, We believe in prolonged expression and trustworthy relationship for China Busbar Machine, Copper Busbar Bending Machine, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

Product Description

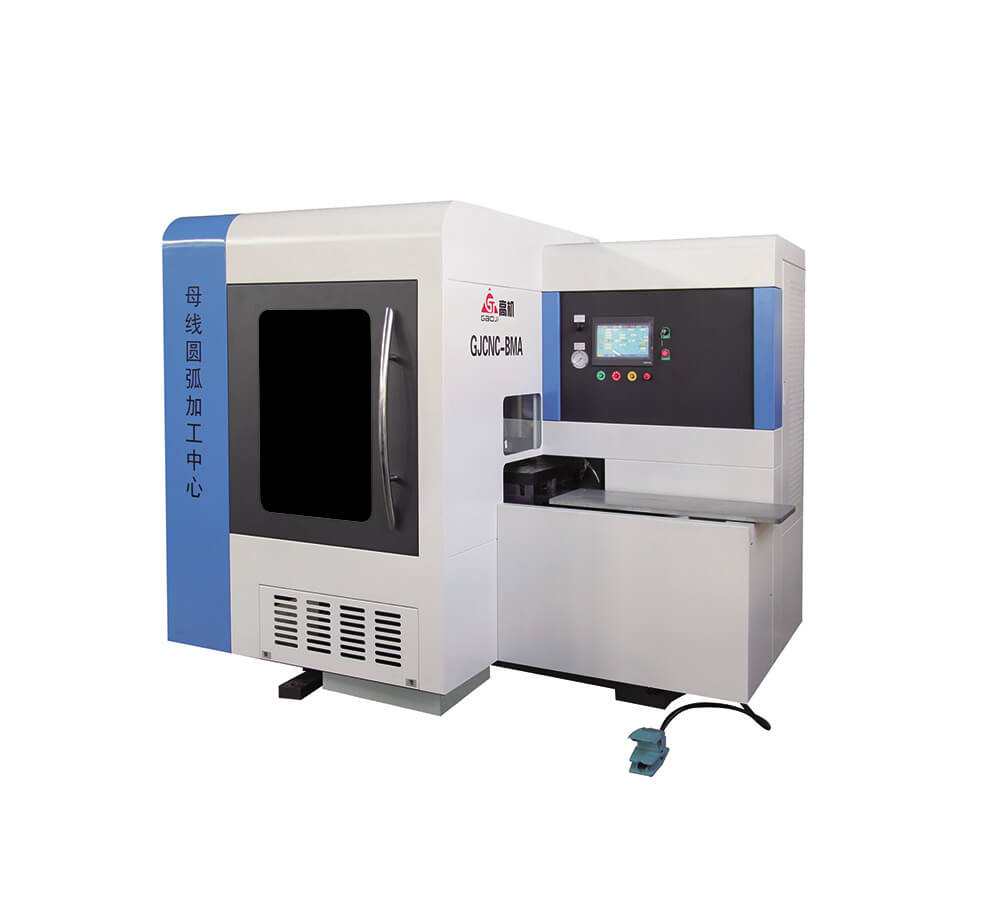

BM603-S-3 Series are multifunction busbar processing machine designed by our company. This equipment could do punching, shearing and bending all at the same time, and specially designed for large size busbar processing.

Advantage

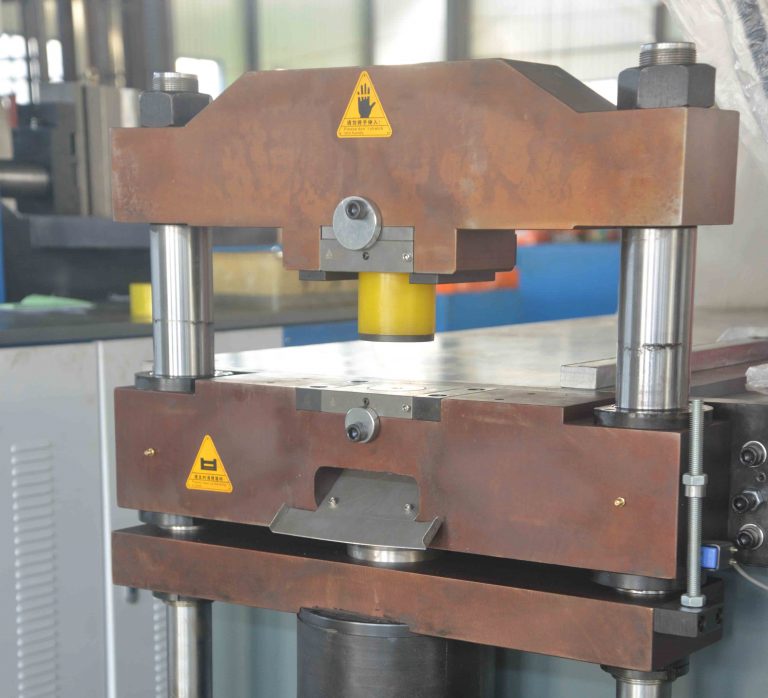

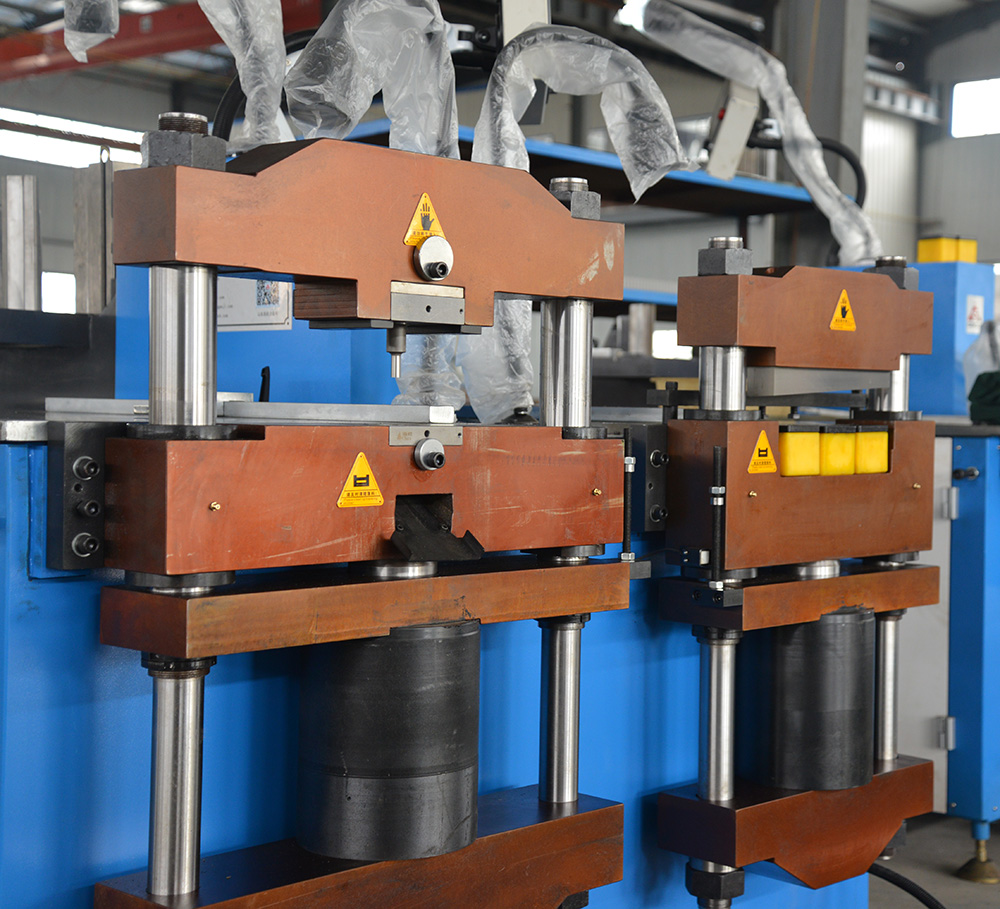

The punching unit adopt column frame, bear reasonable force, can effectively ensure long-term use without deformation. Punching die instal hole was processed by numerical control machine which will ensure high precision and long life, and a lot of process such like round hole, long round hole, square hole, double hole punching or embossing could be completed by changing the die.

The shearing unit also adopt column frame that will provide more power for the knife, the upper and lower knife was installed vertical parallelly, the single shearing mode ensure the kerf smooth with no waste.

The bending unit could process level bending, vertical bending, elbow pipe bending, connecting terminal, Z-shape or twist bending by change the dies.

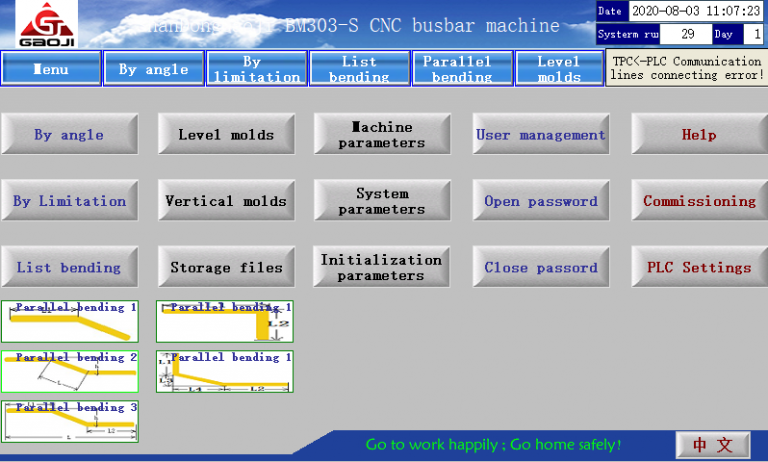

This unit is designed to be controlled by PLC parts, these parts cooperate with our control program could ensure you have easy operate experience and high accuracy workpiece, and the whole bending unit placed on a independent platform which ensure all three units could work at the same time.

Control panel, man-machine interface: he software is simple to operate, has a storage function, and is convenient for repeated operations. The machining control adopts the numerical control method, and the machining accuracy is high.

No matter new buyer or aged buyer, We believe in prolonged expression and trustworthy relationship for Equipment From China CNC Hydraulic Multifunction Busbar Processing Machine, We welcome customers all around the word to speak to us for long run company interactions. Our items are the best. Once Selected, Perfect Forever!

China Busbar Machine, Copper Busbar Bending Machine, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

Product detail pictures:

Related Product Guide:

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with the good quality at the reasonable price for China Wholesale Busbar Processing Equipment Pricelist - China Equipment From China CNC Hydraulic Multifunction Busbar Processing Machine – Gaoji, The product will supply to all over the world, such as: Sri Lanka, Denmark, Oslo, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. Now we have implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our solutions have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We're making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!