China Wholesale 10mm Pipe Bending Spring Quotes - Good quality China Multi CNC Hydraulic Punching Shearing Machine for Copper Busbar – Gaoji

China Wholesale 10mm Pipe Bending Spring Quotes - Good quality China Multi CNC Hydraulic Punching Shearing Machine for Copper Busbar – Gaoji Detail:

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for Good quality China Multi CNC Hydraulic Punching Shearing Machine for Copper Busbar, As we are moving ahead, we hold an eye on our ever-expanding products range and make improvement to our companies.

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for China Busbar Machine, Punching and Shearing Machine, Our items are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is “to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate”.

Product Details

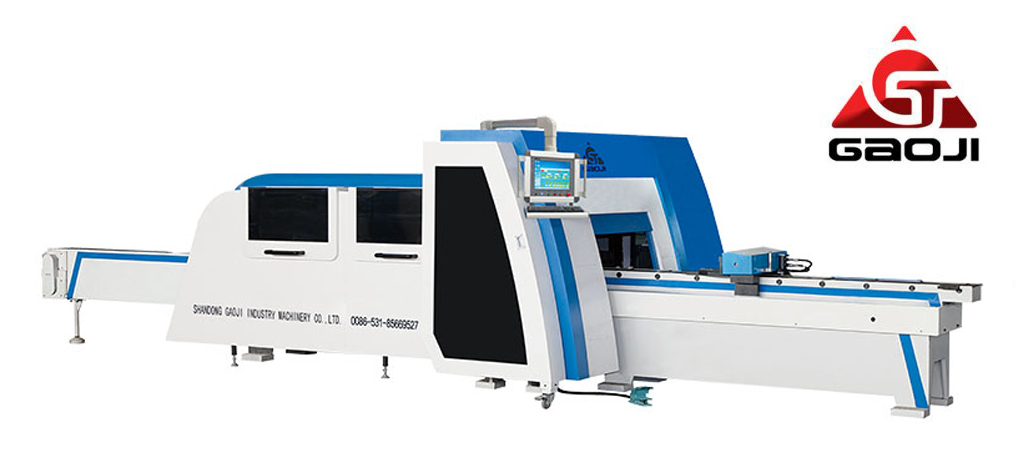

GJCNC-BP-50 is a professional equipment designed to process busbar efficiently and accurately.

During processing this equipment could automatically replace the clamps, which is highly effective especially for long busbar. With those processing dies in the tool library, this equipment could process busbar by punching (round hole, oblong hole etc), embossing, shearing, grooving, cutting filleted corner and so on. The finished workpiece will be delivered by the conveyor.

This equipment can match with CNC bender and form busbar processing production line.

Main Character

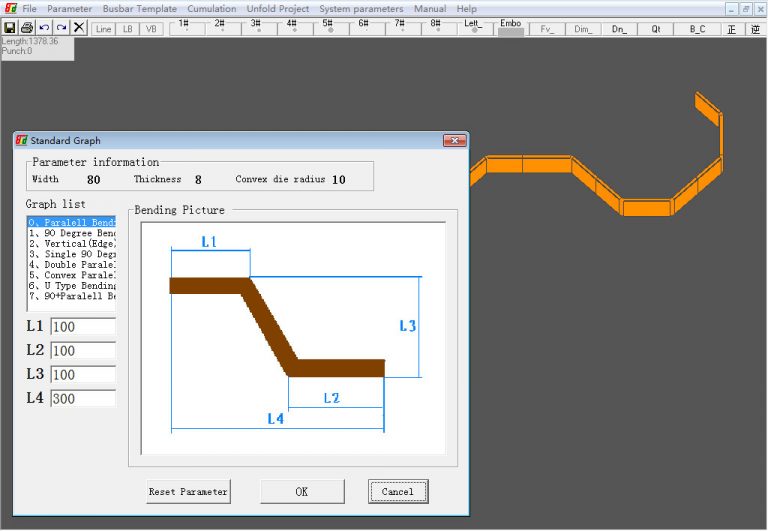

GJ3D / programming software

GJ3D is a special aided design software of busbar processing. Which could auto program machine code, calculate every date in processing, and show you the simulation of the whole process which will present the change of busbar step by step clearly. These characters made it convenient and powerful to avoid complicated manual coding with machine language. And it is able to demonstrate the whole process and effectively prevent material wast cause by incorrect input.

For years out company took the lead on apply 3D graphic technique to busbar processing industry. Now we can present to you the best cnc control and design software in Asian.

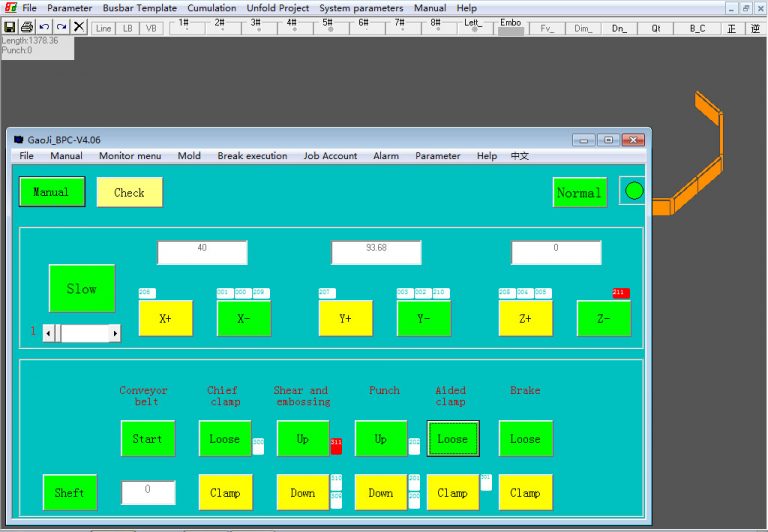

Human-computer interface

In order to present better operation experience and more useful information. The equipment has a 15” RMTP as human-computer interface. With this unit you can have clear information of the whole manufacture process or any alarm might happen and control the equipment by single hand.

If you need to modify the equipment’s setup information or basic die parameters. You can also input the date with this unit.

Mechanical Structures

Inorder to create a steady, effective, precision and long life time mechanical structure, we choose high accurate ball screw, precision linear guide by Taiwan HIWIN and servo system by YASKAWA plus our unique two clamp system. All these above create a transmission system as good as you need.

We develop auto-replace program in order to make the clamp system more effective especially for long busbar processing, and also could maximum reduce operator’s work. Create more value for our customer.

There are two types:

GJCNC-BP-50-8-2.0/SC (Six punching, a shear, a pressing )

GJCNC-BP-50-8-2.0/C (Eight punching, a shear )

You can choose you need models

Export Packing

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for Good quality China Multi CNC Hydraulic Punching Shearing Machine for Copper Busbar, As we are moving ahead, we hold an eye on our ever-expanding products range and make improvement to our companies.

Good quality China Busbar Machine, Punching and Shearing Machine, Our items are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is “to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate”.

Product detail pictures:

Related Product Guide:

We enjoy an extremely good status among our prospects for our great merchandise top quality, competitive price and the ideal service for China Wholesale 10mm Pipe Bending Spring Quotes - Good quality China Multi CNC Hydraulic Punching Shearing Machine for Copper Busbar – Gaoji, The product will supply to all over the world, such as: Costa Rica, Venezuela, Australia, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.