China Gold Supplier for China CNC Lathing Brass Copper Stick Processing Machine

We will make just about every hard work to be excellent and ideal, and accelerate our methods for standing during the rank of intercontinental top-grade and high-tech enterprises for China Gold Supplier for China CNC Lathing Brass Copper Stick Processing Machine, President of our enterprise, with whole personnel, welcomes all buyers to go to our business and inspect. Let us cooperate hand in hand to help make a very good long run.

We will make just about every hard work to be excellent and ideal, and accelerate our methods for standing during the rank of intercontinental top-grade and high-tech enterprises for China Cnc Copper Stick Processing Machine, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our products, just try to contact us for more details!

Product Description

BM603-S-3 Series are multifunction busbar processing machine designed by our company. This equipment could do punching, shearing and bending all at the same time, and specially designed for large size busbar processing.

Advantage

The punching unit adopt column frame, bear reasonable force, can effectively ensure long-term use without deformation. Punching die instal hole was processed by numerical control machine which will ensure high precision and long life, and a lot of process such like round hole, long round hole, square hole, double hole punching or embossing could be completed by changing the die. And also could flattening or shearing copper stick.

The shearing unit choose the single shear method, make no scrap while shearing the material.

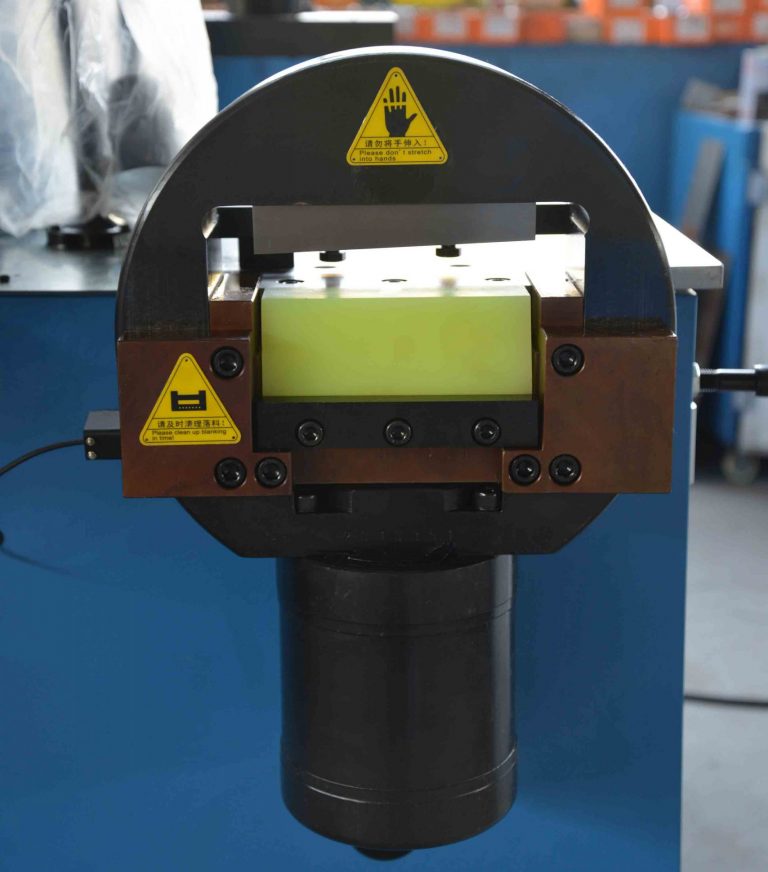

And this unit adopts round integral structure which is effective and capable of long service life.

The bending unit could process level bending, vertical bending, elbow pipe bending, connecting terminal, Z-shape or twist bending by change the dies.

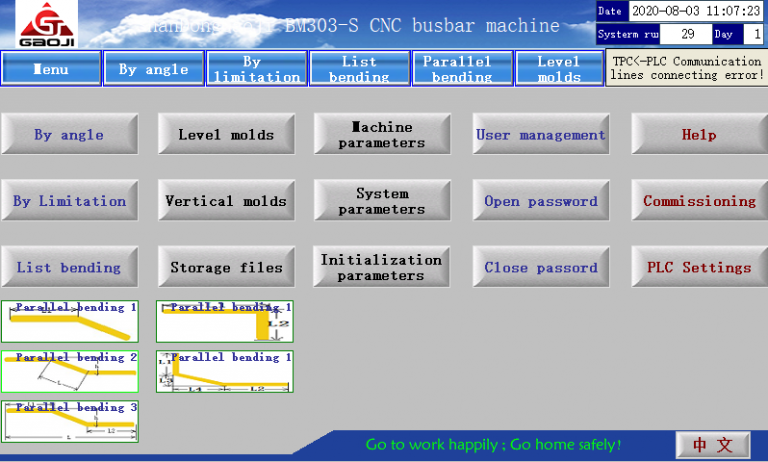

This unit is designed to be controlled by PLC parts, these parts cooperate with our control program could ensure you have easy operate experience and high accuracy workpiece, and the whole bending unit placed on a independent platform which ensure all three units could work at the same time.

The bending unit could process level bending, vertical bending, elbow pipe bending, connecting terminal, Z-shape or twist bending by change the dies.

This unit is designed to be controlled by PLC parts, these parts cooperate with our control program could ensure you have easy operate experience and high accuracy workpiece, and the whole bending unit placed on a independent platform which ensure all three units could work at the same time.

Control panel, man-machine interface: he software is simple to operate, has a storage function, and is convenient for repeated operations. The machining control adopts the numerical control method, and the machining accuracy is high.

China Cnc Copper Stick Processing Machine

We will make just about every hard work to be excellent and ideal, and accelerate our methods for standing during the rank of intercontinental top-grade and high-tech enterprises for China Gold Supplier for China CNC Lathing Brass Copper Stick Processing Machine, President of our enterprise, with whole personnel, welcomes all buyers to go to our business and inspect. Let us cooperate hand in hand to help make a very good long run.

China Gold Supplier for China Stick Pin, CNC Turning, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our products, just try to contact us for more details!

Configuration

| Work Bench Dimension (mm) | Machine Weight (kg) | Total Power (kw) | Working Voltage (V) | Number of Hydraulic Unit (Pic*Mpa) | Control Model |

| Layer I: 1500*1200Layer II: 840*370 | 1500 | 11.37 | 380 | 3*31.5 | PLC+CNCangel bending |

Main Technical Parameters

| Material | Processing Limite (mm) | Max Output Force (kN) | ||

| Punching unit | Copper / Aluminum | ∅32(16*160mm) ∅25(Copper stick) | 600 | |

| Shearing unit | 15*160 (Single Shearing) 12*160 (Punching Shearing) | 350 | ||

| Bending unit | 15*160 (Vertical Bending) 12*120 (Horizontal Bending) | 350 | ||

| * All three units could be chosen or modify as customization. | ||||